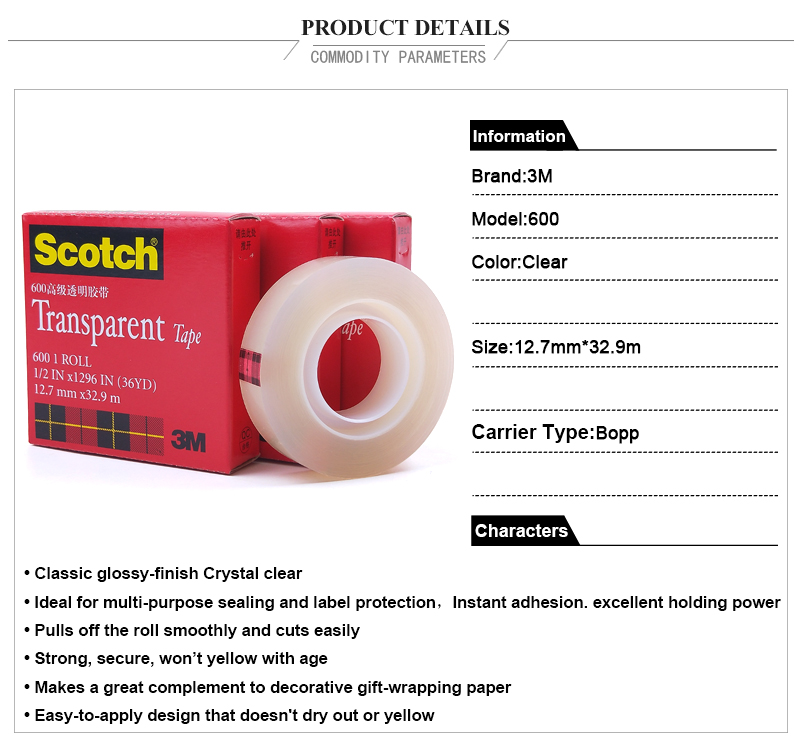

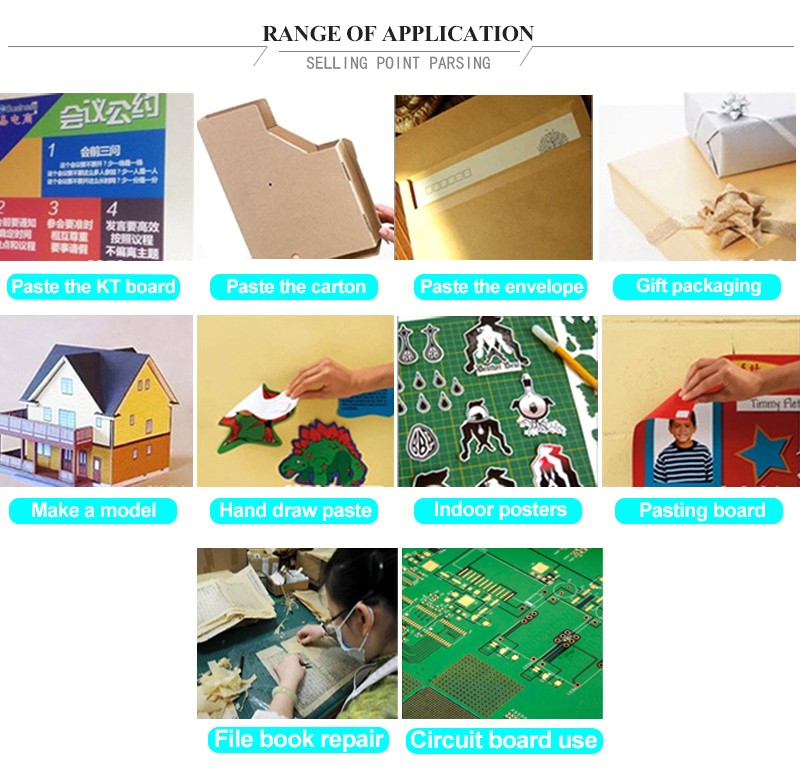

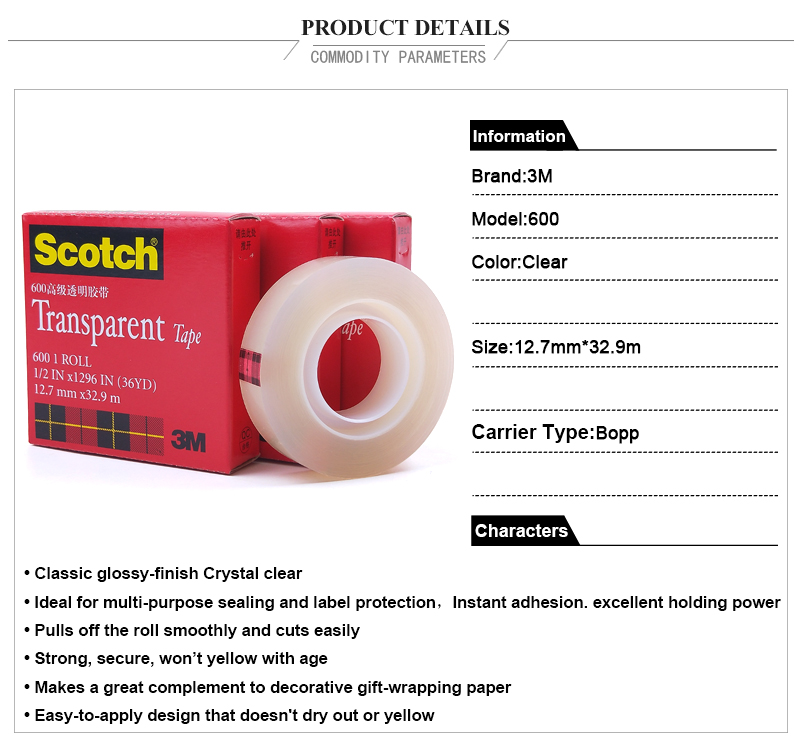

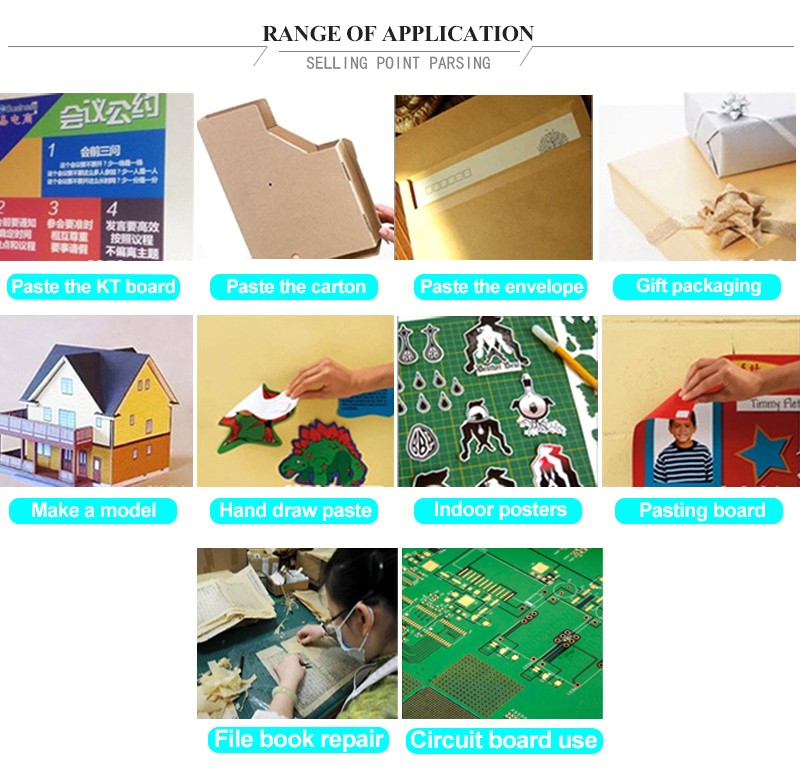

3M® Tape 600 is a transparent film tape that is excellent for various packaging applications. It has a pressure sensitive acrylic adhesive system which is long agin and highly transparent, so it has stain and sunlight resistance which makes it an excellent choice for use on fabrics. Recommended for gift-wrapping, combining, attaching, light duty carton sealing and miscellaneous store use

Typical Physical

Properties

Note: The following technical information and data should be considered representative or typical only, and should not be used for specification purposes.

|

| ASTM Test Method |

Adhesion to Steel: | 28 oz./in. width (30 N/100 mm) | D-3330 |

Machine Direction Tensile Strength: | 28 lbs./in. width (490 N/100 mm) | D-3759 |

Elongation at Break: | 45% | D-3759 |

Tape Thickness - Backing: | 1.5 mil (0.038 mm) | D-3652 |

Total: | 2.3 mil (0.058 mm) | D-3652 |

Features

Easy-release treated.

Meets CID A-A-113 Type 1 Class A.

Moisture and chemical resistance.

Roll stability.

Long aging.

Controlled, smooth unwind.

Unaffected by changing atmospheric conditions and resistant to many acids, alkalies and solvents.

Has good edge tear and breakage resistance.

Easy to read through.

Excellent holding and good dispensing properties.

Does not yellow on fabrics

Available Sizes

Standard Widths: | 3/8 in., 1/2 in., 3/4 in., 1 in., 11/2 in., 2 in. |

Available by Special Order: | Custom widths and lengths available on request, |

| subject to minimum order requirements. |

|

|

Core Size (ID): | 3 in. |

|

|

Lengths: | 72 yds. |

Application Techniques | An extensive line of manual, semi-automatic and automatic equipment is available |

| to facilitate application of 3M® Tape 600. |

|

|

Storage Conditions | Storage of 3M® Tape 600 at 70°F (21°C) and 40-50% relative humidity is |

| recommended. |

|

|

Shelf Life | To obtain best performance, use this product within 18 months from date of |

| manufacture. |

Technical Information

The technical information, recommendations and other statements contained in this document are based upon tests or experience that 3M believes are reliable, but the accuracy or completeness of such information is not guaranteed.

Product Use

Many factors beyond 3M’s control and uniquely within user’s knowledge and control can affect the use and performance of a 3M product in a particular application. Given the variety of factors that can affect the use and performance of a 3M product, user is solely responsible for evaluating the 3M product and determining whether it is fit for a particular purpose and suitable for user’s method of application.