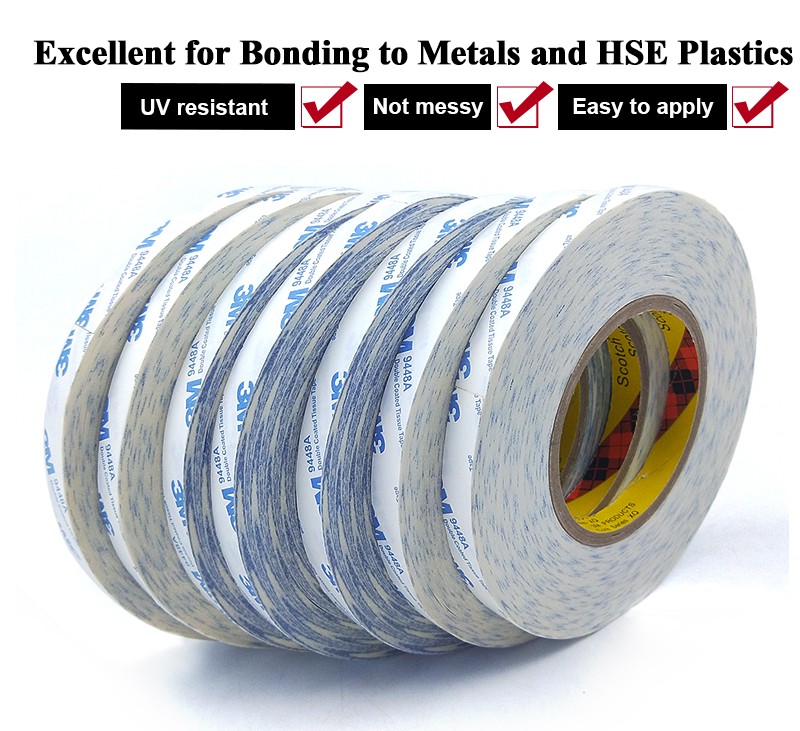

3m 9448a Pressure sensitive Adhesive Tapes

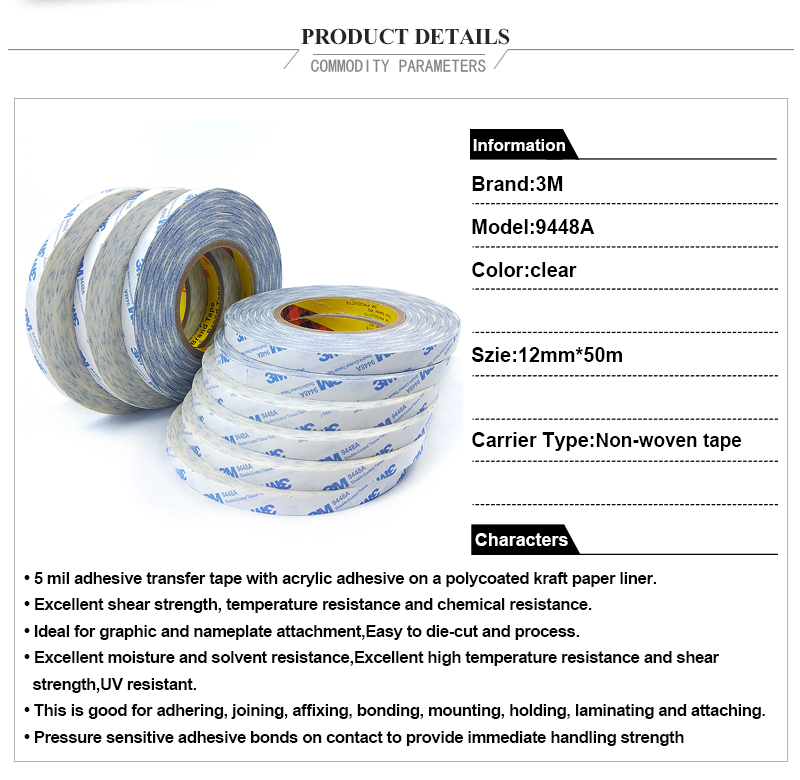

1. Bond strength is dependent upon the amount of adhesive-to-surface contact developed. Firm application pressure develops better adhesive contact & thus improves bond strength.

2. To obtain optimum adhesion, the bonding surfaces must be clean dry and well unified. A typical surface cleaning solvent is isopropyl alcohol & water. Use proper safety precautions for handling solvents.

3. Ideal tape application temperature range is 21°C to 38°C.

Initial tape application to surfaces at temperatures below 10°C is not recommended because the adhesive becomes too firm to adhere readily. However once properly applied low temperature holding is generally satisfactory.

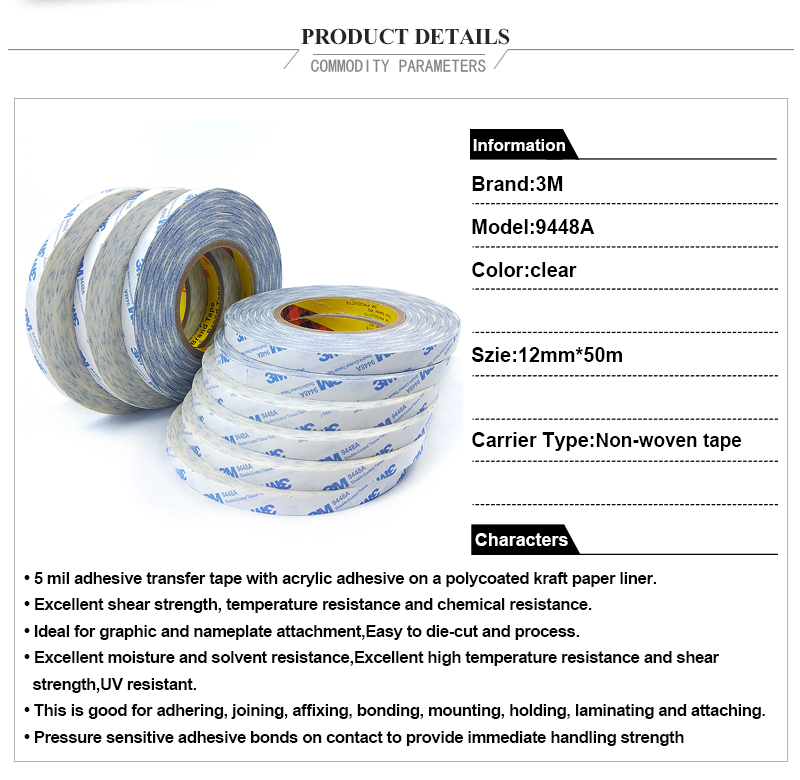

Details:

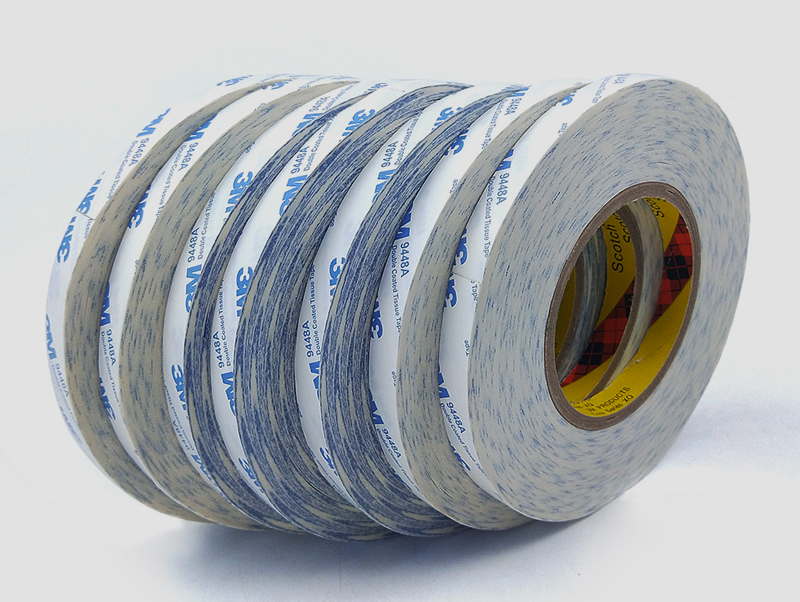

3m double sided adhesive tissue tape

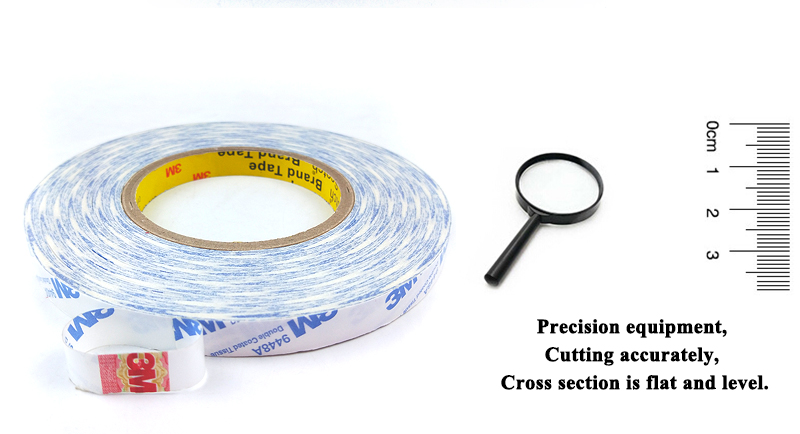

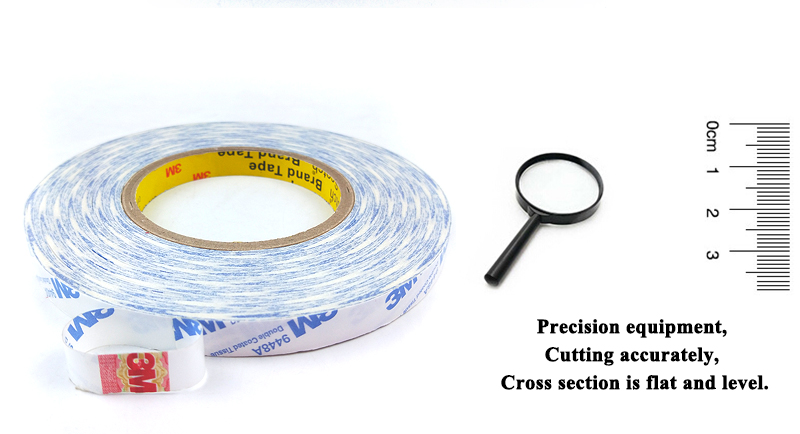

Thickness 0.15mm

material:tissue

size:1200mm*50M we can die cut as per your request

Item:9448A

Material: Non-woven tissue | Adhesive Side: Double Sided | Adhesive: Acrylic |

Adhesive Type: Pressure Sensitive | Design Printing: No Printing | Place of Origin: China (Mainland) |

Brand Name: 3M | Model Number: 9448A | Thickness: 0.15mm |

Color: clear |

|

|

Specifications

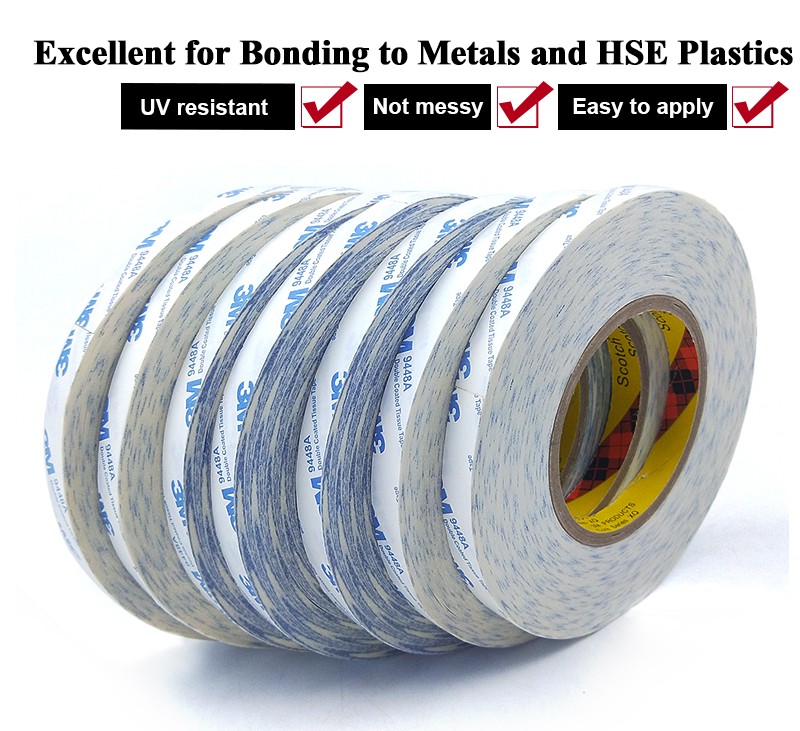

It has a very high level of initial tack and good adhesion to a wide variety of surfaces including LSE material.

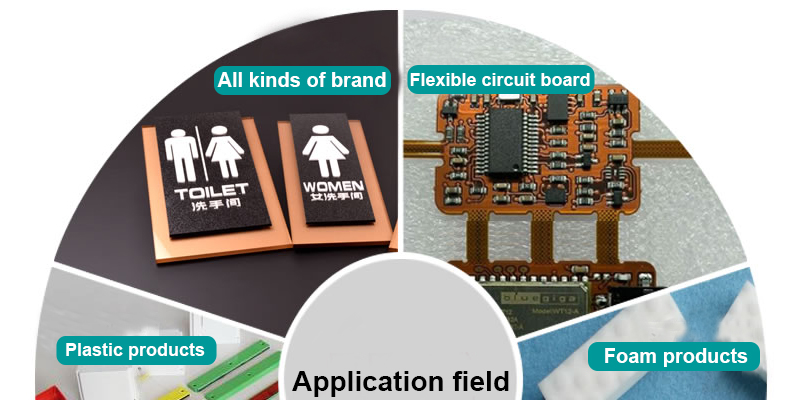

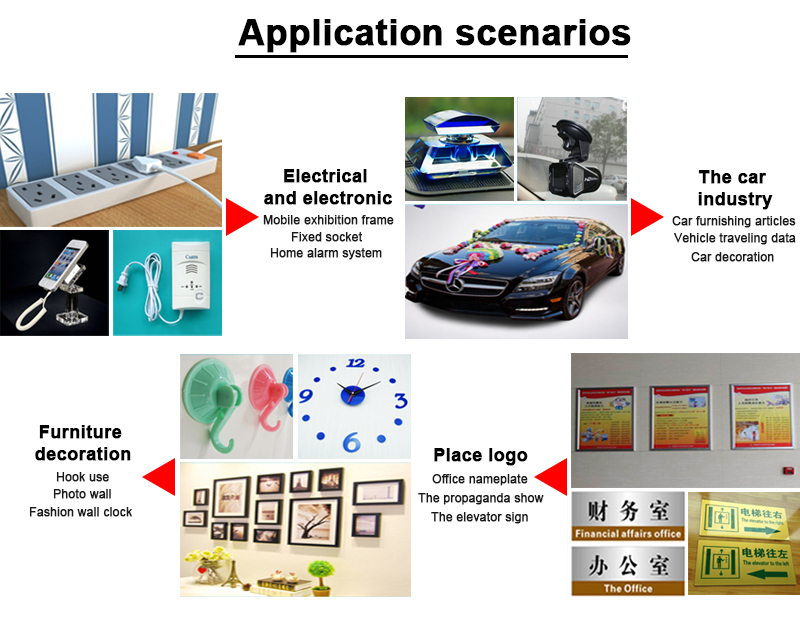

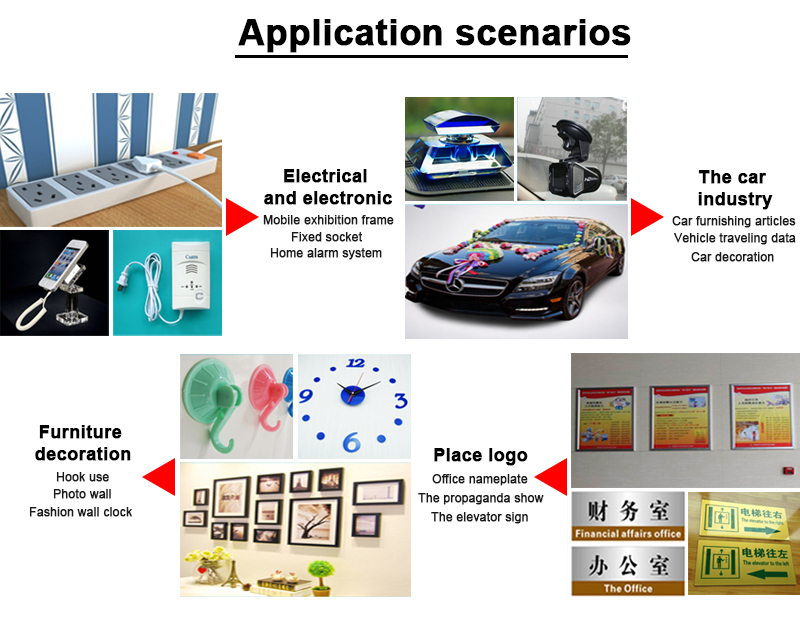

Applications:

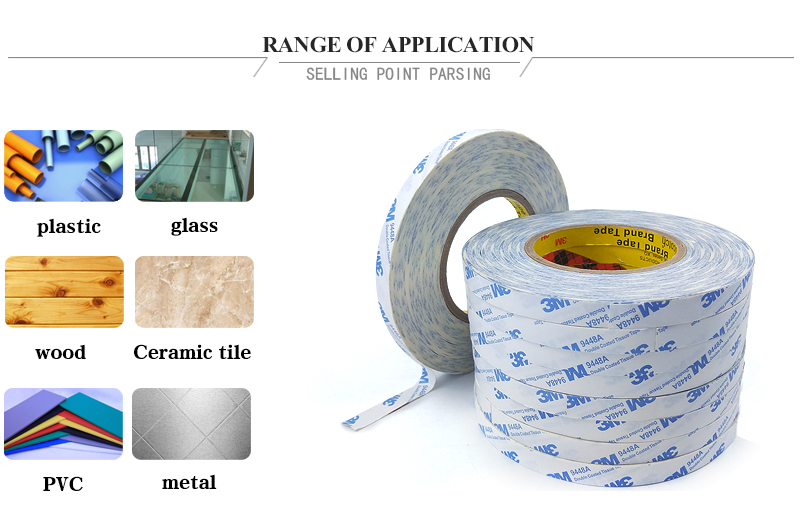

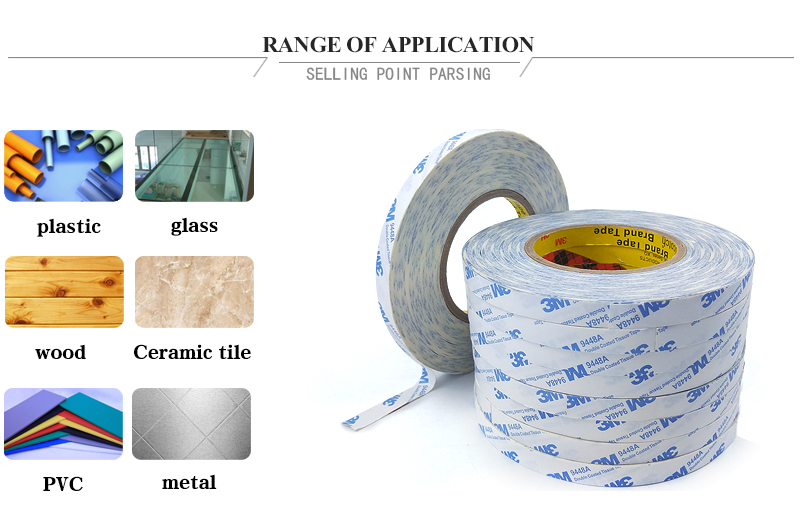

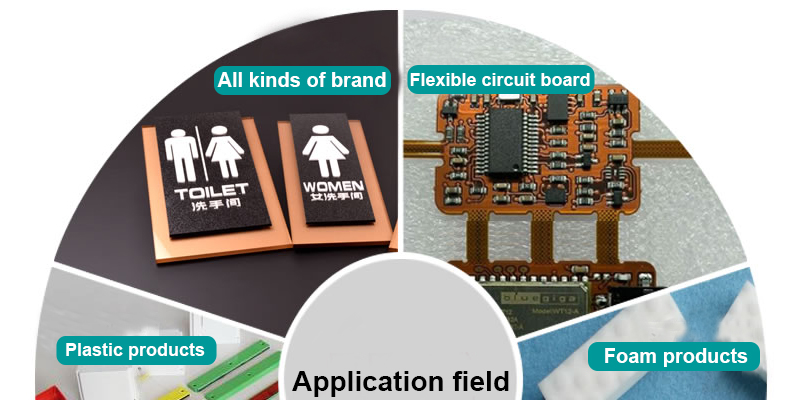

9448 is well suited to bonding together a wide variety of similar and dissimilar materials such as wood, metals, glass, papers, paints and many plastics and fabrics.

It shows a high level of adhesion to LSE materials such as Polypropylene and some Polyethylenes as well as coated papers and varnishes.

Application Techniques:

1. Bond strength is dependent upon the amount of adhesive-to-surface contact developed. Firm application pressure develops better adhesive contact & thus improves bond strength.

2. To obtain optimum adhesion, the bonding surfaces must be clean dry and well unified. A typical surface cleaning solvent is isopropyl alcohol & water. Use proper safety precautions for handling solvents.

3. Ideal tape application temperature range is 21°C to 38°C. Initial tape application to surfaces at temperatures below 10°C is not recommended because the adhesive becomes too firm to adhere readily. However once properly applied low temperature holding is generally satisfactory.